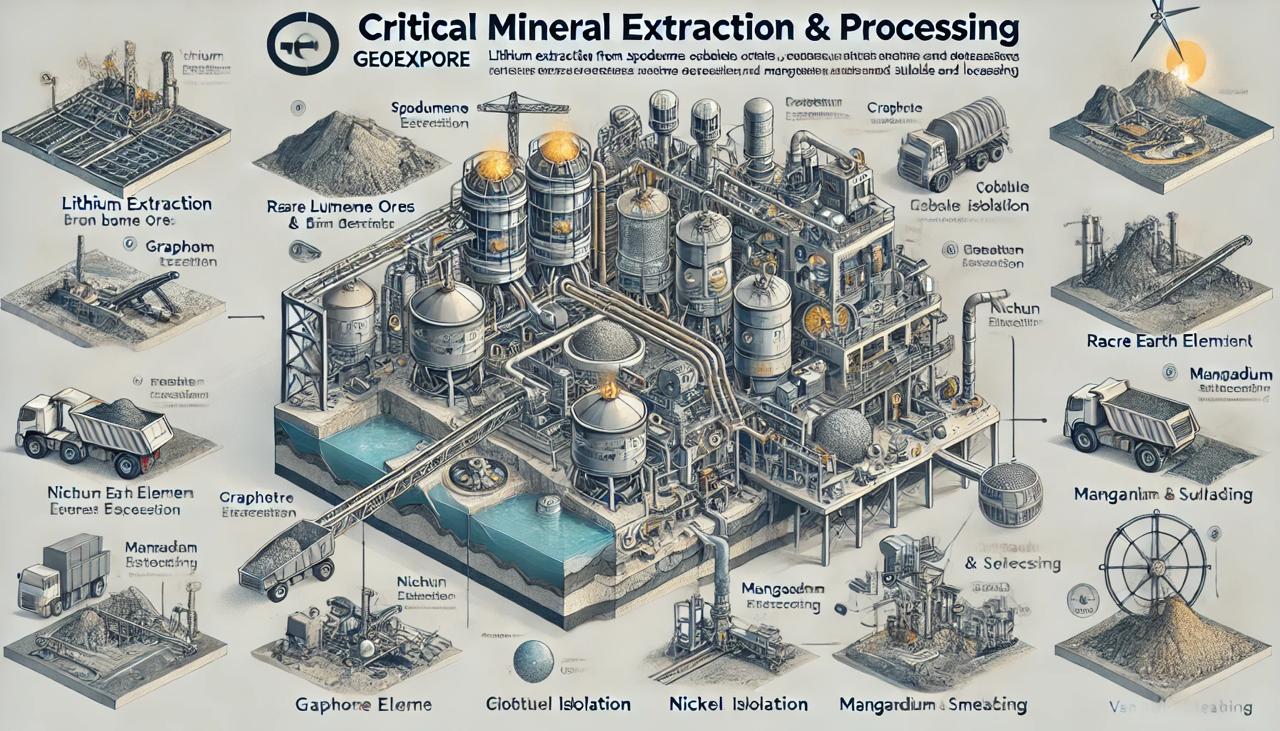

The modern world runs on a vast array of critical minerals. From powering electric vehicles to enabling green technologies and advanced electronics, these minerals form the backbone of our technology-driven era. GeoExpOre, with its expertise in mineral exploration and processing, specializes in extracting and refining these essential resources through advanced and efficient methodologies.

What Are Critical Minerals?

Critical minerals are those essential to economic and national security, and whose supply chain is vulnerable to disruptions. They include elements like lithium, cobalt, rare earth elements (REEs), graphite, manganese, and nickel, among others. These minerals are integral to the production of batteries, renewable energy technologies, electronics, and high-tech defense systems. Given their significance, ensuring a reliable and efficient supply chain is crucial—and this is where GeoExpOre applies its technical proficiency.

Technical Expertise in Extraction and Processing

GeoExpOre specializes in a range of advanced extraction and processing techniques tailored to the unique requirements of different critical minerals. Each mineral has distinct geological and chemical characteristics, which demand specialized approaches for successful extraction and refinement. Here’s an in-depth overview of the processes GeoExpOre employs to extract and process some of the world’s most sought-after critical minerals:

1. Lithium

Lithium, a key component in rechargeable batteries, is extracted from either spodumene ores or lithium brine deposits. GeoExpOre employs advanced technologies for both sources:

- Hard Rock (Spodumene) Extraction: For spodumene ore, the process starts with mining, followed by crushing, grinding, and flotation to concentrate lithium-bearing minerals. The concentrate is then subjected to calcination and acid leaching to extract lithium carbonate or lithium hydroxide.

- Lithium Brine Extraction: Direct lithium extraction (DLE) techniques are utilized for extracting lithium from brine deposits, which improves recovery rates and minimizes environmental impact.

2. Cobalt

Cobalt, primarily a by-product of nickel and copper mining, is vital for battery production. The processing techniques used maximize recovery and efficiency:

- Hydrometallurgical Techniques: Using solvent extraction and electrowinning, cobalt is efficiently isolated from other metals, ensuring high-purity production suitable for battery applications.

3. Rare Earth Elements (REEs)

REEs, often found in complex mineral matrices, require sophisticated separation techniques:

- Crushing and Beneficiation: The process begins with crushing and grinding, followed by physical beneficiation techniques such as gravity separation, magnetic separation, and froth flotation to concentrate the rare earth minerals.

- Solvent Extraction: A specialized solvent extraction process is employed to separate individual REEs, optimizing yield and reducing impurities for high-tech applications.

4. Graphite

Graphite is essential for lithium-ion battery anodes and various industrial uses:

- Flotation and Purification: For natural graphite, the process involves flotation to create a concentrate, followed by thermal or chemical purification to achieve the high purity levels required for battery-grade graphite.

- Spherical Graphite Processing: Graphite concentrate is further processed into spherical graphite, a preferred form for battery anodes, through milling and classification techniques.

5. Nickel

Nickel is crucial for high-performance batteries and stainless steel production:

- Laterite and Sulfide Ore Processing: GeoExpOre utilizes both hydrometallurgical (pressure acid leaching) and pyrometallurgical (smelting) techniques, depending on the ore type, to ensure efficient nickel recovery and waste minimization.

6. Manganese

Manganese is used in steelmaking and battery cathodes:

- Pyrometallurgical Smelting: For manganese ores, smelting techniques are employed to extract ferromanganese or electrolytic manganese metal, both essential for alloy production and battery technology.

7. Vanadium

Vanadium is gaining prominence for its use in redox flow batteries:

- Roasting and Leaching: Roasting is used to convert vanadium ore into soluble compounds, followed by leaching and precipitation to obtain vanadium pentoxide, which can be refined for battery and alloy applications.

Sustainable and Innovative Approaches

GeoExpOre is committed to using sustainable and innovative approaches throughout the extraction and processing stages. The focus is on reducing energy consumption, minimizing environmental impact, and optimizing resource use. Cutting-edge technologies such as AI-driven mineral targeting, advanced leaching methods, and eco-friendly reagent usage are incorporated to enhance efficiency and sustainability.

GeoExpOre’s Technical Edge

GeoExpOre’s advantage lies in its end-to-end technical expertise—spanning exploration, extraction, and processing—backed by a strong technical team with extensive industry knowledge. The team is adept at understanding the geological complexities and applying tailored solutions to deliver high-quality critical minerals that meet the stringent demands of the modern world.

With a vision to contribute meaningfully to the global supply chain of critical minerals, GeoExpOre is driving innovation, efficiency, and sustainability in mineral processing, ensuring a reliable supply of resources that enable tomorrow’s technologies.

Contact GeoExpOre for technical insights and collaborations in the field of critical mineral extraction and processing.

By : Channamallikarjun B.Patil