Mineral Processing

Mineral Processing Plant Design

Designing a mineral processing plant involves several key principles and considerations to ensure efficient and effective operations. GeoExpOre specilises in the same with some of the finest Mineral Processing Plant design engineers working with us.

Layout

The plant layout should be designed to optimize the flow of materials and minimize handling costs.

It must accommodate the necessary equipment and allow for future expansions.

Process Flow

A well-defined process flow is crucial for maximizing recovery rates and minimizing operational costs.

The flow should be designed to handle variations in ore quality and quantity.

Infrastructure Requirements

Adequate infrastructure is needed to support the plant's operations, including power supply, water management, and waste disposal systems.

Consideration of environmental

impacts and compliance with

regulations is essential.

Equipment Selection for Mineral Processing

Efficiency

Equipment must be capable of processing the ore efficiently, maximizing throughput and recovery rates. Consideration of energy consumption and operational efficiency is crucial.

Cost-Effectiveness

Initial capital costs and ongoing maintenance costs should be evaluated.Equipment should provide a good balance between cost and performance.

Suitability for Different Ore Types

Equipment must be adaptable to different ore characteristics and processing requirements. The ability to handle variations in ore composition and hardness is essential.

Role of Mineral Processing in Exploration

01

Understanding Ore Potential

Mineral processing knowledge is vital in assessing

the economic viability of ore deposits during

exploration.

It helps in determining the feasibility of extracting

valuable minerals efficiently.

02

Defining Ore Characteristics

Understanding the physical and chemical properties of the ore is crucial for designing effective processing strategies.

This knowledge aids in selecting the appropriate

processing techniques and equipment.

03

Improving Resource Estimation

Accurate resource estimation is enhanced through detailed mineral processing analysis.

It ensures reliable predictions about the quantity and quality of the extractable minerals, guiding investment and development decisions.

Mine Closure and Environmental Considerations

Mine Closure Strategies

Develop comprehensive closure plans that include land rehabilitation, infrastructure removal, and ecosystem restoration.

Engage stakeholders early in the planning process to ensure sustainable and community-friendly outcomes.

Environmental Considerations

Implement waste management systems that minimize environmental impact and ensure safe disposal of tailings and other by-products.

Adhere to strict regulatory compliance to protect local ecosystems and water resources.

Regulatory Compliance

Stay updated with local and international mining regulations to ensure all closure activities meet legal standards.

Conduct regular environmental audits to assess and mitigate potential risks.

Dewatering and Tailing Dam Design

Dewatering Process

Objective: Remove excess water from mineral processing operations to optimize efficiency and ensure safety.

Methods: Utilize technologies such as centrifuges, filters, and thickeners.

Considerations: Focus on energy efficiency, minimizing water usage, and ensuring the quality of discharged water

meets environmental standards

Tailing Dam Desig

Objective: Safely store byproducts of mineral processing operations while minimizing environmental impact.

Design Elements:

- Structural Integrity: Ensure the dam can withstand natural events like earthquakes or heavy rainfall.

- Environmental Safeguards: Implement measures to prevent contamination of surrounding ecosystems.

- Monitoring Systems: Install real-time monitoring for early detection of potential failures.

Economic and Risk Considerations in Mineral Processing

01

Cost and Investment Decisions

Evaluate the capital and operational expenditures to ensure profitability.

Consider the lifecycle costs of equipment and

infrastructure.

Conduct feasibility studies to guide investment

decisions.

02

Risk Mitigation

Identify potential risks such as market fluctuations, environmental impacts, and operational hazards.

Develop contingency plans and insurance strategies to manage risks.

Implement safety protocols and compliance

measures to minimize operational risks.

03

Financial Modeling

Use financial models to project cash flows and assess project viability.

Analyze scenarios to understand the impact of different variables on financial outcomes.

Incorporate sensitivity analysis to evaluate the effects of changes in key assumptions.

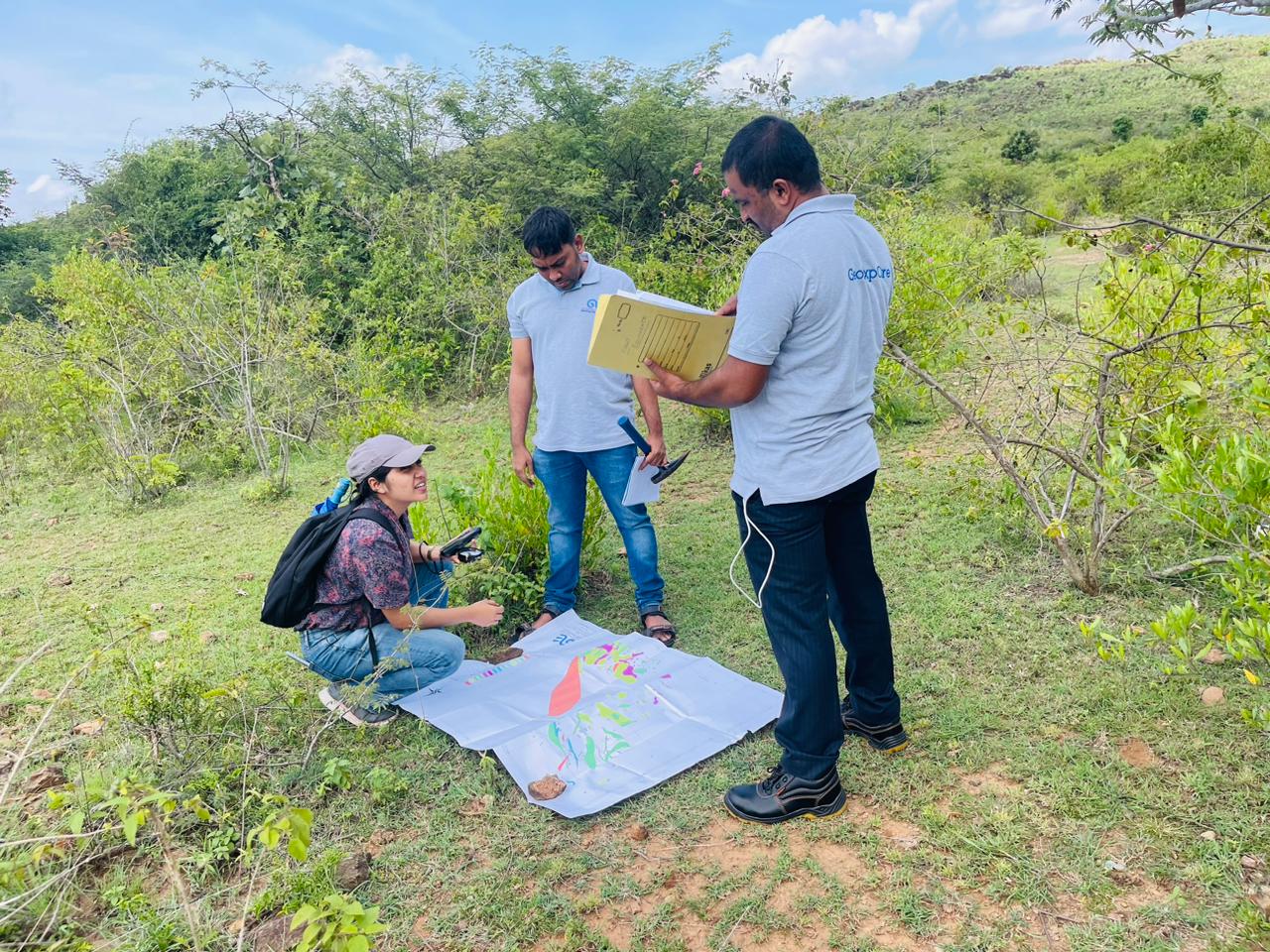

AI for Mineral Processing by GeoExpOre

Equipment Selection

The selection of equipment for mineral processing using AI should consider energy consumption, costeffectiveness, and suitability for different ore types.

Energy Consumption

AI can be used to optimize energy consumption in mineral processing by analyzing data from sensors and predicting energy usage. This can lead to significant cost savings and reduced environmental impact.

Effectiveness

AI can help identify the most cost-effective equipment for mineral processing by analyzing data on equipment performance, maintenance costs, and energy usage. This can lead to significant cost savings and improved profitability

Suitability for Different Ore Types

AI can be used to analyze data on different ore types and predict the most effective equipment for each type. This can lead to improved efficiency and reduced waste.